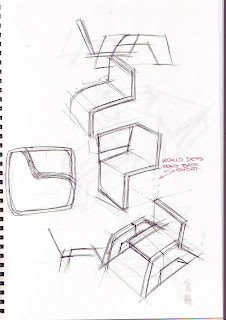

This design is all kinds of awesome! Very simple as it is two exactly the same pieces slotted together. I would really like to pursue this idea however after speaking to the workshop guys they believe it would be too flimsy as too much material is cut away in order for the 2 pieces to slot together. Also angular cuts would need to be made which would be an absolute pain. will try and work around this however!